Calibrating

your Volksmeter

The Volksmeter

(VM) is an unusual

seismic instrument, having at its heart a

simple short pendulum. The general principle of operation is

straight forward, being a sensitive detector which measures the

displacement

of the pendulum, and which will therefore indicate either a tilt or

horizontal acceleration of the whole instrument. When

considering a modern automobile engine, the theory of

operation can get rather complex upon close inspection, and similarly

with 'simple' pendulums and how they behave. The inventor of the

Volksmeter is a particular authority on the motion of pendulums and has

written extensively on the subject. In an appendix to the

comprehensive Volksmeter

User

Manual, there is a detailed

theory

of

operation

covering seismometer detectors in general,

and pendulums in particular.

One of the useful features of acceleration sensors is

the ability to calibrate them by tilting them with respect to the

Earth's gravitational field, and so it is with the Volksmeter.

Because of its extreme sensitivity, particularly when operated in

24-bit mode, the Volksmeter can take quite some taming, and some

practice with setup is required. The technique for leveling the

VM is

covered quite

well in the on-line user manual in Chapter

2b.

Assuming that the reader has completed their Volksmeter's installation

at a

permanent site, and is operating it via WinSDR, there remains the

question of

what sensitivity figures should be entered into WinSDR's 'Sensor

information'

page, for both the acceleration channels (Channels 1 & 2) and

the velocity channels (Channels, 3 & 4). For Channels 1 &

2

this sensitivity figure represents the amount of horizontal

acceleration required to register a change of 1-bit by the VM's

detector.

WinSDR may be configured with various sensitivities by setting

the digitisation range anywhere between

16-bit to 24-bit operation. When operated in 24-bit mode the VM

is

very

sensitive

indeed and can be tricky to work with, due to flexure

of just about everything within and external to the instrument.

At these levels of sensitivity,

'hard' substances such as reinforced concrete floor support, can

effectively become a big slab of marshmallow.

The calibration process is relatively

straight forward, and utilises the VM's leveling screws. These

screws

are arranged in a triangle, with a single screw located on the left

hand side

(LHS) of the

instrument, and two screws on the right hand side (RHS). Consider

turning just the LHS leveling screw, which will cause

the whole instrument to tilt

about an axis running between the tips of the two RHS leveling

screws. Since we know that the thread pitch of the leveling

screws is 32 turns-per-inch, and the horizontal distance between the

LHS leveling screw tip and axis of rotation is 9.70 inches (246mm),

then a

single turn of the LHS screw will cause the whole instrument to tilt by

arctan(1/32"÷9.7")

=

0.185º

=

0.00322

radians.

When operated in 24-bit mode, the VM's digitiser output ranges between

±8,388,608 'counts'. In practice, and considering

just

Channel 2, it takes a little less than two complete turns of the LHS

screw to cause the digitiser output to range between the maximum -ve

counts and

maximum +ve counts. I have found that 1½ turns of the

LHS screw

can be comfortably accommodated within the 24-bit digitisation

span. Firstly

it is helpful to calculate the VM's counts/tilt ratio, normally

expressed in units of counts/radian. By adjusting the LHS screw

to a point

near maximum -ve counts, and then rotating it 1½ turns toward

+ve

counts, one can compute this ratio. For example, I adjusted the

LHS screw to a point where I read a figure of -7,129,000 counts, and

after rotating the screw 1½

turns anticlockwise, this figure became +7,670,000

counts. Taking the difference between these two and dividing by

1½,

yields

a

figure

of

around

9,866,000

counts/turn.

But one screw

turn changes the tilt by 0.00322

radians,

so

the

counts/radian

figure

for

my

particular

VM

is ≅2.0×109

counts/radian. Note that this figure is for 24-bit digitisation,

and it will be reduced for

lower-resolution digitisation. For example, for 20-bit

digitisation it would be reduced by a factor of 16.

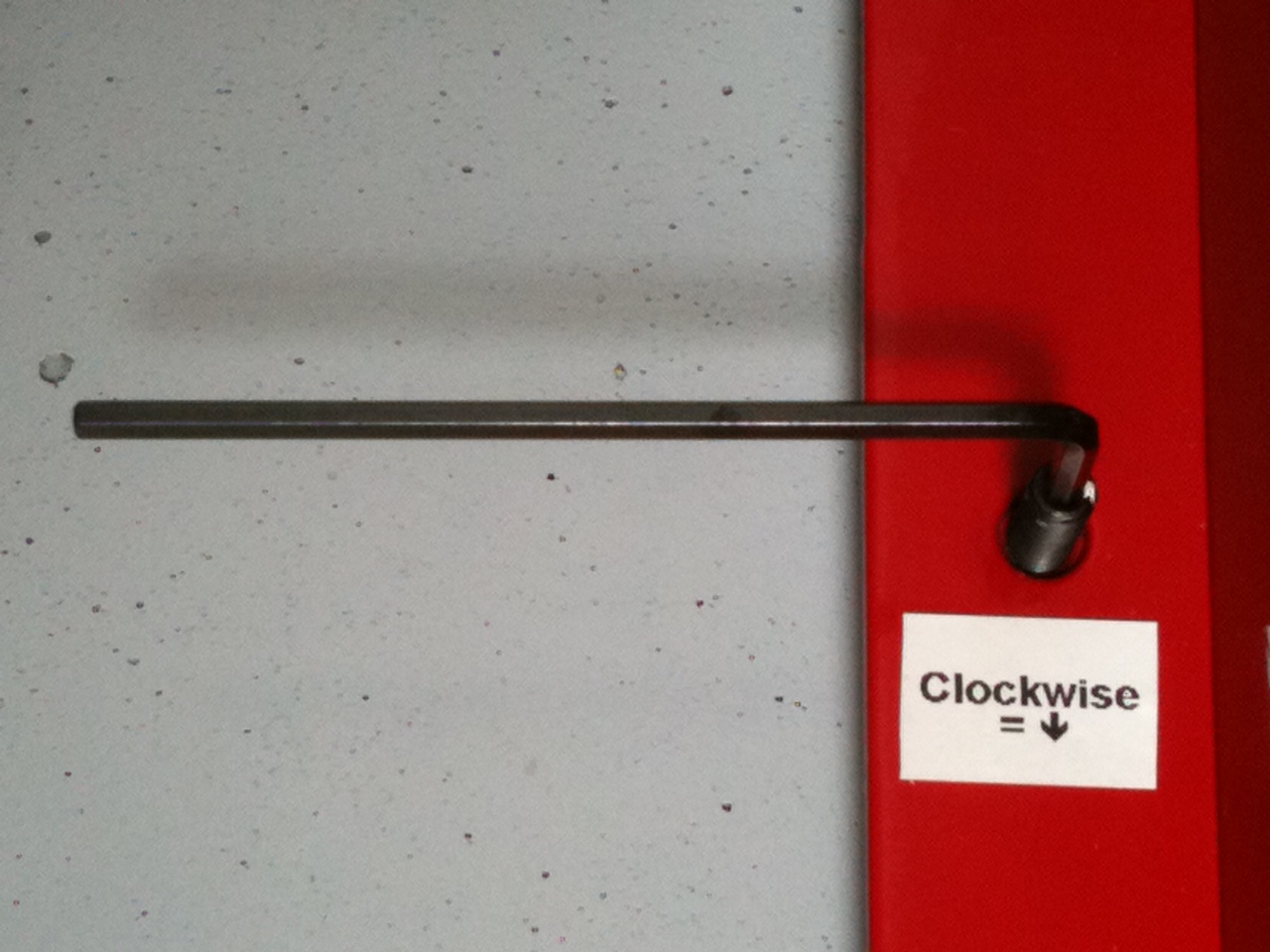

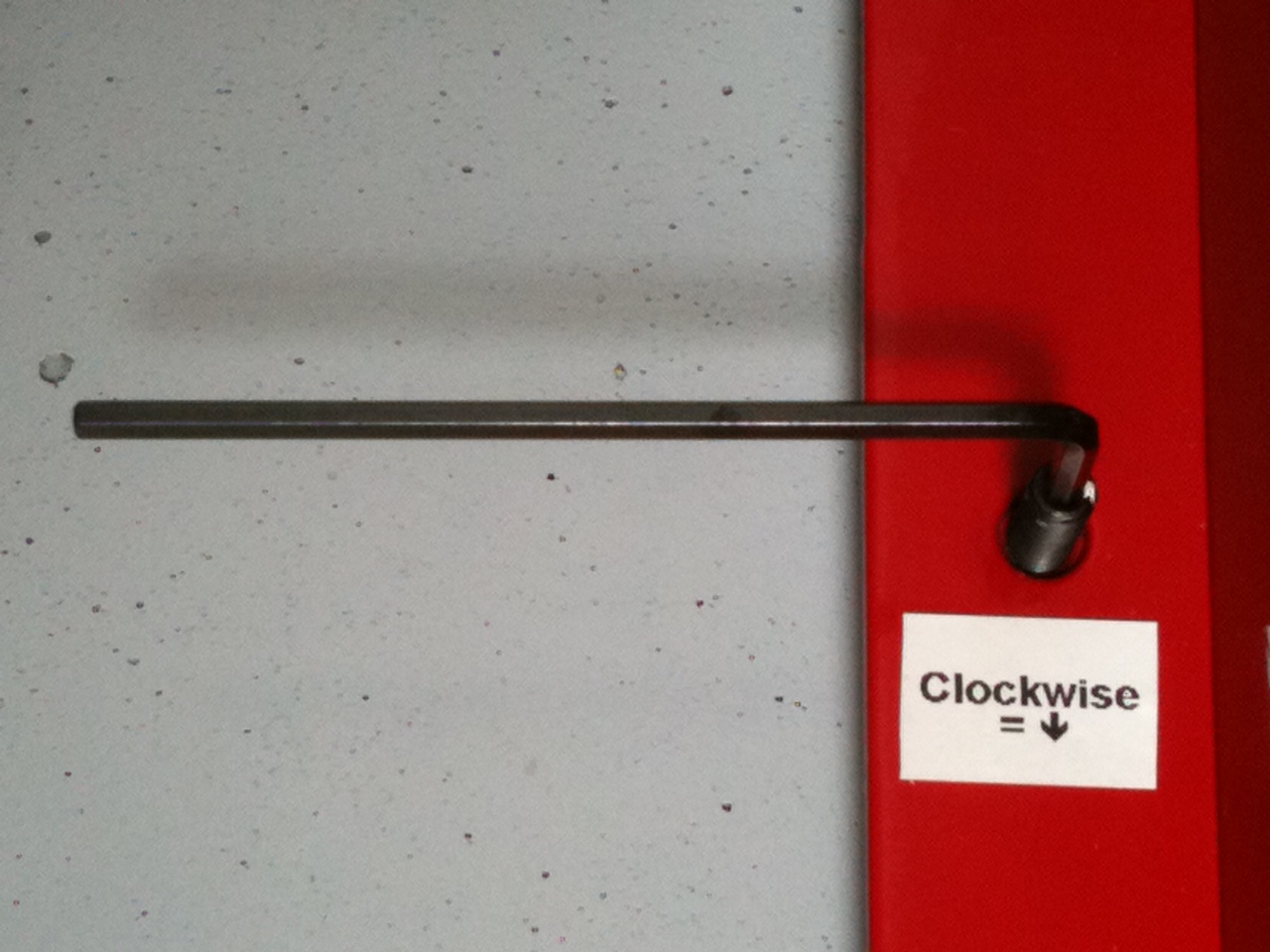

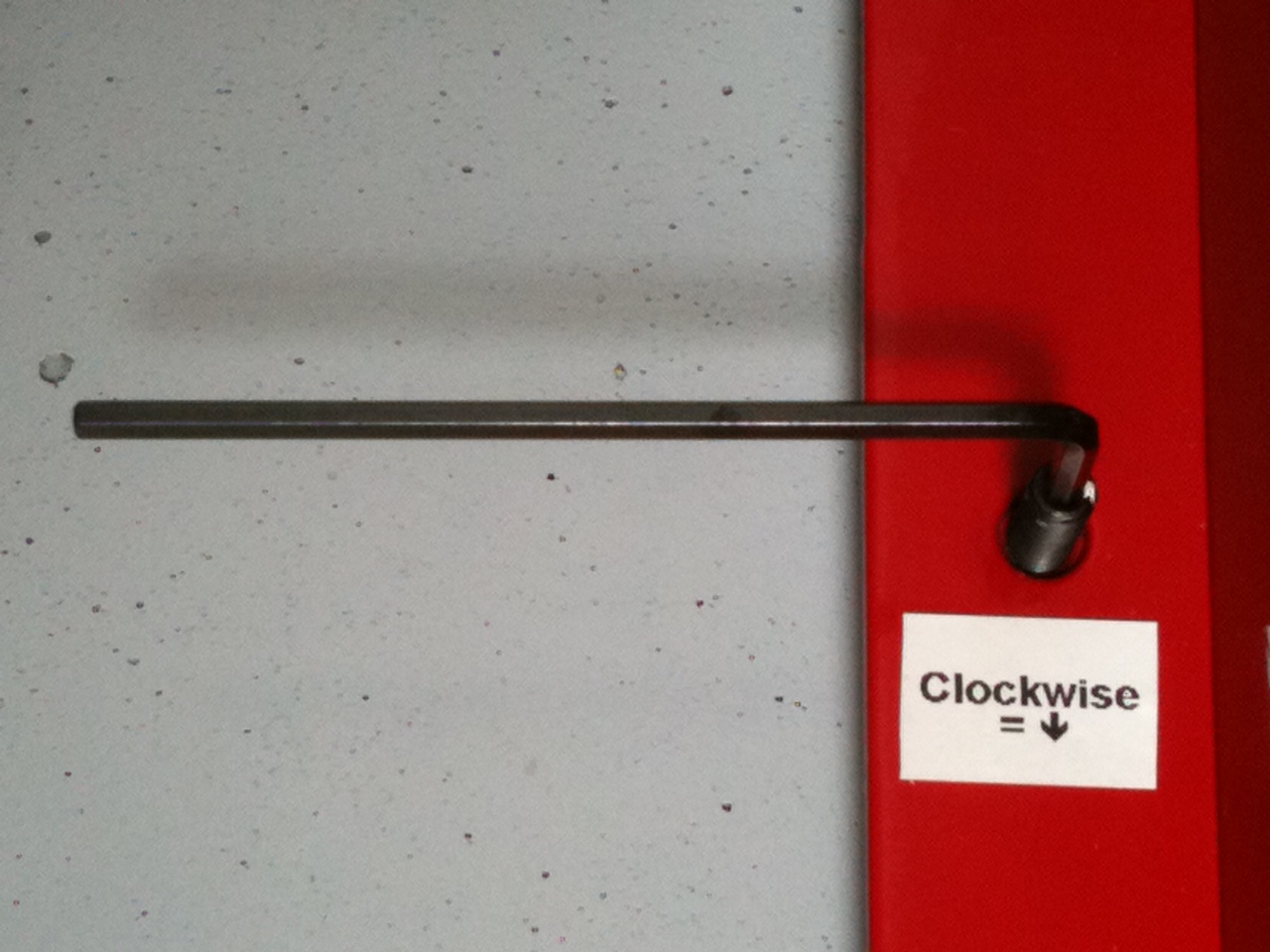

As a point of technique for accurately rotating a

leveling screw by 1½

turns

(or

any

other

amount),

I

recommend

placing

a tiny dot of white

paint (e.g. typewriter correction fluid) on the top of the screw to

indicate its general rotation position (it's easy to lose track of

rotation

otherwise). One may then use a 3/32"

Allan key to rotate the screw. As may be seen in the right-hand

image,

the

Allan

key

shaft

also

acts as an

analog pointer,

and

one

can

fairly

accurately

eyeball when the Allan key is pointing

directly away from the instrument or when it is aligned parallel with

the edge of the VM base plate. Another handy tip, which may also

be seen in this image, is to label the effect that screw rotation has

on WinSDR's screen trace. In this case, a clockwise rotation will

cause the WinSDR screen trace to move downwards (i.e. towards -ve

digitiser counts). This knowledge

can save a lot of mucking around when leveling the instrument.

As a point of technique for accurately rotating a

leveling screw by 1½

turns

(or

any

other

amount),

I

recommend

placing

a tiny dot of white

paint (e.g. typewriter correction fluid) on the top of the screw to

indicate its general rotation position (it's easy to lose track of

rotation

otherwise). One may then use a 3/32"

Allan key to rotate the screw. As may be seen in the right-hand

image,

the

Allan

key

shaft

also

acts as an

analog pointer,

and

one

can

fairly

accurately

eyeball when the Allan key is pointing

directly away from the instrument or when it is aligned parallel with

the edge of the VM base plate. Another handy tip, which may also

be seen in this image, is to label the effect that screw rotation has

on WinSDR's screen trace. In this case, a clockwise rotation will

cause the WinSDR screen trace to move downwards (i.e. towards -ve

digitiser counts). This knowledge

can save a lot of mucking around when leveling the instrument.

The standard textbook constant for 'g', the vertical acceleration due

to

Earth's gravity, is 9.80665m/s/s

(SI

units)

=

980.665cm/s/s

(cgs

units, used by WinSDR). A single rotation of the

LHS leveling screw will introduce a horizontal component of

acceleration of 1/32"÷9.7"x980.665

= 3.159cm/s/s. So in terms of acceleration/counts, for one turn

of the screw and 24-bit digitisation, the figure for my particular VM

is 3.159/9,866,000

≅

3.2x10-7cm/s/s/count,

which

is

the

required figure to enter

into WinSDR's

sensor

sensitivity

field (specifically enter "3.2e-007" into this

field). On the same setup page the 'Output Type' field needs to

be set

to 'Acceleration'. The

'Output

Voltage',

'Amp

Gain'

and

'A/D

Input' fields

don't apply to the VM and may be set to 0.0. Working on the

assumption that VM channels 1 & 2 have

similar performance,

I have set both my Channel 1 & 2 sensitivity fields to "3.2e-007".

This is well and good for the VM acceleration channels 1 & 2, but

what about the

VM velocity channels 3 and 4? What figure should be entered for

the sensor sensitivity here? This was a small puzzle for me for

quite some time, and I firstly tried the hit-and-miss adjustment

technique, by observing actual teleseismic quakes and by comparing my

measured peak ground velocities with those modeled by the USGS arrival

time calculator. This produced pleasingly consistent results,

but

still not exactly a calibrated value.

This puzzle was solved one day by the realisation that WinQuake has a

digital integration function, and it should therefore be possible

to digitally integrate one of the VM's acceleration channels, and to

compare it with a VM

channel which produces velocity output directly (e.g. integrated data

from VM Channel 1 should be very similar to that from Channel 3).

Exactly how WinSDR produces its real-time velocity channels (3 &

4), by performing a real-time integration of acceleration, is an

algorithmic 'black

box', but it seems to work well enough. If one takes a hour's

worth of VM acceleration data (say Channel 1, preferably containing

something interesting such as a teleseismic quake), and then

integrates it

via WinQuake, and then prints out the resultant trace, this visually

compares quite well with the trace of Channel 3 data acquired over the

same period. On close

inspection the two traces won't be exactly

the same, but usually pretty close, as may be seen with this

example showing integrated acceleration (upper trace) and

velocity (lower trace).

One thing to note when integrating data from VM Channels 1 & 2, is

that small consistent accelerations (i.e. tiny slow near-DC changes in

tilt occurring within the data period) can lead to some very peculiar

looking (e.g. banana

shaped) velocity traces. After

integrating VM

acceleration data, it is advisable to then apply a high-pass filter of

say 0.01Hz, to remove the near-DC components left over from integration.

WinQuake's 'Calculate

RMS' function may then be used to calculate the velocity

sensitivity figure. Firstly, enter a 'first guess' sensitivity

figure

for WinSDR channels 3 & 4 by entering "3.00e-007" into the

sensitivity fields. Then take a hour's worth of VM Channel 1

data, integrate it, filter it, and calculate the RMS velocity.

Then take the channel 3 data for the same period and calculate its RMS

velocity. These two RMS numbers will not match, but will likely

be

similar. For example, if the integrated acceleration [Channel 1]

RMS figure was 40um/s and the velocity [Channel 3] RMS was

30um/s, then Channel 3 velocity needs to be scaled up by a factor of

40/30. This would require multiplying the 'first guess'

sensitivity by 4/3, that is 3.0x10-7

x 4/3 = 4.00e-007 in

this case. With my particular VM instrument,

I have determined my Channel 3 & 4 sensitivity figure to be

"3.89e-007".

Each individual Volksmeter will need its own calibration,

but as an intermediate step to get a new VM owner up-and-running, I

suggest entering the following sensitivity constants into WinSDR's

sensor sensitivity fields.:

VM Channel

no.

|

Sensor

sensitivity

|

1

|

3.20e-007 |

2

|

3.20e-007 |

3

|

3.89e-007 |

4

|

3.89e-007 |

I would be interested to know what calibration figures other VM owners

have found, so please feel welcome to email me and I will post

the

results on this page.

2010-02-14

As a point of technique for accurately rotating a

leveling screw by

As a point of technique for accurately rotating a

leveling screw by  As a point of technique for accurately rotating a

leveling screw by 1½

turns

(or

any

other

amount),

I

recommend

placing

a tiny dot of white

paint (e.g. typewriter correction fluid) on the top of the screw to

indicate its general rotation position (it's easy to lose track of

rotation

otherwise). One may then use a 3/32"

Allan key to rotate the screw. As may be seen in the right-hand

image,

the

Allan

key

shaft

also

acts as an

analog pointer,

and

one

can

fairly

accurately

eyeball when the Allan key is pointing

directly away from the instrument or when it is aligned parallel with

the edge of the VM base plate. Another handy tip, which may also

be seen in this image, is to label the effect that screw rotation has

on WinSDR's screen trace. In this case, a clockwise rotation will

cause the WinSDR screen trace to move downwards (i.e. towards -ve

digitiser counts). This knowledge

can save a lot of mucking around when leveling the instrument.

As a point of technique for accurately rotating a

leveling screw by 1½

turns

(or

any

other

amount),

I

recommend

placing

a tiny dot of white

paint (e.g. typewriter correction fluid) on the top of the screw to

indicate its general rotation position (it's easy to lose track of

rotation

otherwise). One may then use a 3/32"

Allan key to rotate the screw. As may be seen in the right-hand

image,

the

Allan

key

shaft

also

acts as an

analog pointer,

and

one

can

fairly

accurately

eyeball when the Allan key is pointing

directly away from the instrument or when it is aligned parallel with

the edge of the VM base plate. Another handy tip, which may also

be seen in this image, is to label the effect that screw rotation has

on WinSDR's screen trace. In this case, a clockwise rotation will

cause the WinSDR screen trace to move downwards (i.e. towards -ve

digitiser counts). This knowledge

can save a lot of mucking around when leveling the instrument.